Re-greasing the Astro-3 equatorial mount |

I bought the

Lidl-refractor in December 2005. I have equipped the Astro-3

equatorial mount with a Vixen MT-1 motor in the RA-axis. The purpose is

to use it as a light-weight travel mount. Pictures of the assembled

mount and a description of how I mounted the motor to

the equatorial head is described in

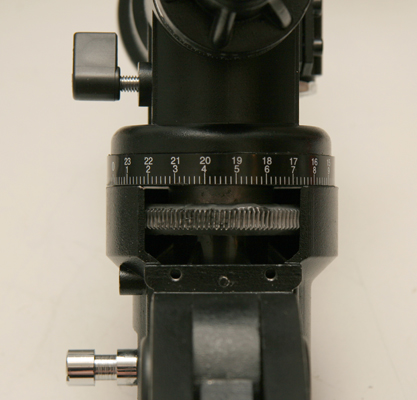

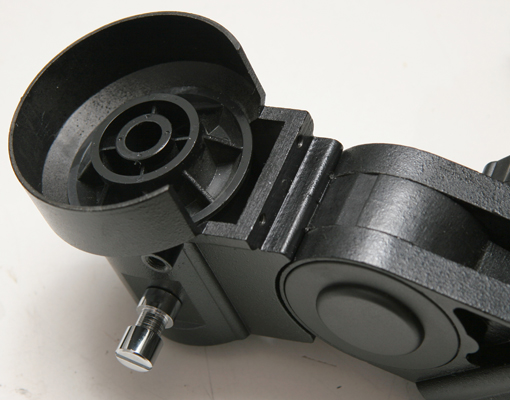

another page. GreasingThe original grease used by the factory is more like glue. I decided to replace this grease. This is a fairly simple operation.Start by removing the cover for the worm gear: |

| Here

we see the gear of the RA-axis, |

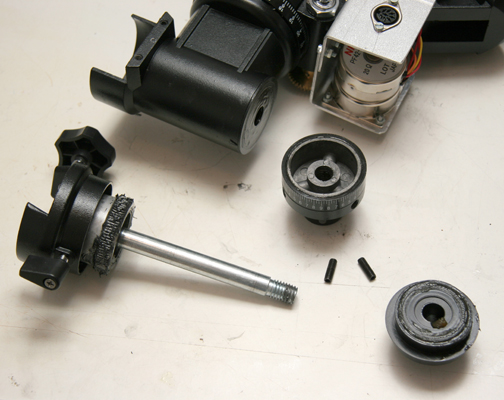

| and

the various parts of the worm drive (after cleansing in white spirit). |

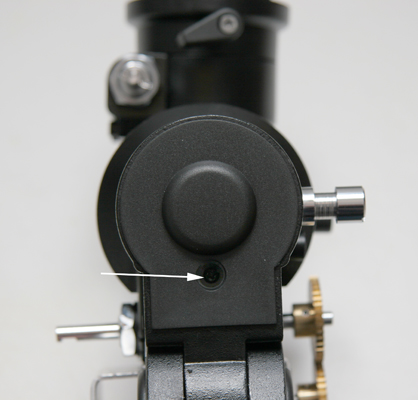

| Remove

the cover at the bottom of the RA-axis by loosening the screw indicated

by arrow. |

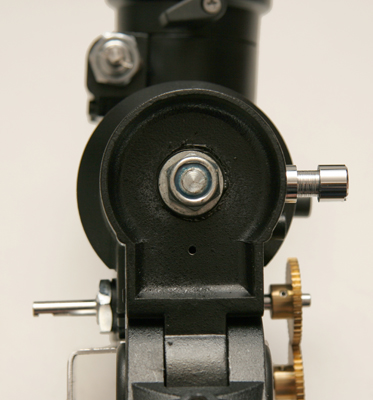

| Loosen

the nut with a 17mm wrench. |

| Pull

out the assembly. |

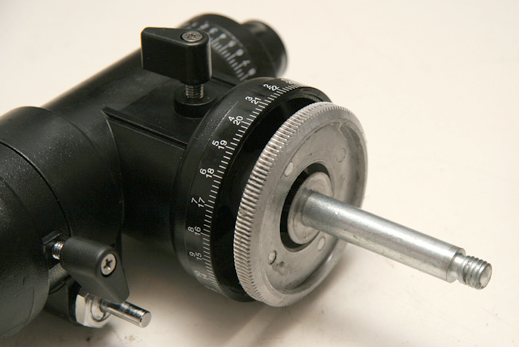

| Detail

of gear-wheel (after cleansing). It has 138 teeth. However, I have

heard

reports of samples with 139 teeth as well. If you plan to motorize with

computer control you should know this number for calculating correct

speed. |

| The bearing-housing of the RA-axis. The upper bearing is plastic. The løower bearing is just a hole in the metal bottom of the housing. |

| All

parts of the RA-axis assembly can be released by loosening the locking

screw in the upper part of the picture. Pull out the gear.

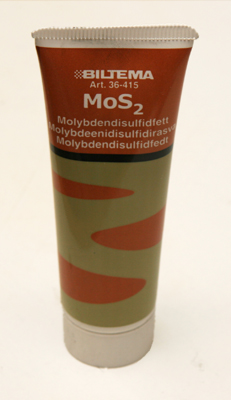

Clean the parts in white spirit and apply a grease suited for the

temperature range where you live. I used the grease shown below: |

| Then,

put all pieces together. When you thighten the nuts that fasten the

RA-axis and the worm-drive axis you have to be careful not to use too

much force. If you use too much force the drive will not rotate easily.

If you use to little force, the mount will be unstable. The axis should

run freely, but with a firm feel. The Declination axis can be dismantled by removing the worm gear housing, loosening the 2 locking screws in the big nut with the setting circle. |

| Pull

axis out of the housing, clean all parts and apply new grease. Put all

pieces back together. Again using just the right momentum to ensure

that the axis revolves freely but without slack. |

© 2006 Odd Høydalsvik

![]()